Building Homes with Life-Size Lego Bricks

If you’ve ever wondered what it would be like to build life-size houses with large Lego bricks, wonder no more! The childhood dream of building a life-size Lego house is now a reality. Renco USA, a Florida construction firm, has created intuitive building blocks that connect just like Lego bricks: and they are catching on quickly.

These giant interlocking blocks work much like Lego bricks and can be quickly put together to create floors, walls, roofs, and more — all they need is a special adhesive and to be pounded in with a rubber mallet. Since glue and a mallet are all that’s needed, fewer workers are required to get the job done.

“We worked on this [system] for more than 10 years,” RENCO co-founder Tom Murphy, Jr. told Engineering News Record. “We had to keep changing it to make it better and easier to work with. As we did that, making a building with it got faster and easier, and… the building got stronger each time.”

In an industry where there is around a 5-million housing start backlog, methods like this can be the solution to meet the ever-growing demand for high quality housing.

Who is RENCO?

RENCO is the creator of RENCO, a state-of-the-art structural building system that uses glass-fiber reinforced mineral composite bricks and adhesives. RENCO alone is certified and approved to design and build mineral composite fiber reinforced structures under the International Building Code. RENCO is also fully patent protected.

Thomas P. Murphy, Jr. and Engin Yesil are the co-founders of RENCO, with Kenneth A. Smuts as acting President. The company’s executive team, which also includes Patrick E. Murphy CPA and Executive VP Vedat Valkuz, has over 100 years of proven construction experience.

How Life Size Lego Building Works

The process is similar to injection molding, in which the systems’ proprietary material can be made into a variety of shapes— whether it’s LEGO bricks, beams, joists, and much more. There’s no more need for welding, cutting, or masonry on-site. Finished block walls function just like traditional concrete, making it easy for plumbers, electricians, and HVAC techs install other household systems without any adaptations.

RENCO’s unprecedented building system uses methyl methacrylate glue and recycled glass fiber. This patented mineral composite, fiber-reinforced (MCFR) building system is less affected by supply chain issues. A methyl methacrylate bonding agent fuses MCFR pieces together. No welding, nailing, or cutting metal required.

Currently, the RENCO Structural Building System can build up to five story structures. The company hopes to get approval to build up to eight stories by the end of this year.

- Want to see it in action? Watch RENCO’s YouTube video that shows the process first-hand!

Construction Worker using a hammer to install a RENCO brick. Photo credit: Renco-Usa.com

The Palm Springs Construction Project

Though RENCO has done many international projects, the company has taken on their first stateside project in Palm Beach County, Florida. It is a $21 million, 96- unit housing complex made up of four 3-story buildings — and it’s being built by just 11 workers. The goal of this project is to demonstrate the many advantages RENCO’s system has over wood, concrete, and steel, while respecting the construction site’s surroundings.

“It’s our privilege to share this revolutionary building concept with you and trust you will see the possibilities we provide,” RENCO states on its website.

At the Palm Springs construction site, there are no lifts, cranes, saws, welding machines, or obtrusively loud noises. The only tools the workers are using are rubber mallets and glue guns. The project has become an economic and time-saving solution, providing much-needed housing.

“We were excited to hear about a project that was more affordable that could be put up more quickly than standard construction,” said Palm Springs vice mayor Kimberly Glas-Castro to ENR.

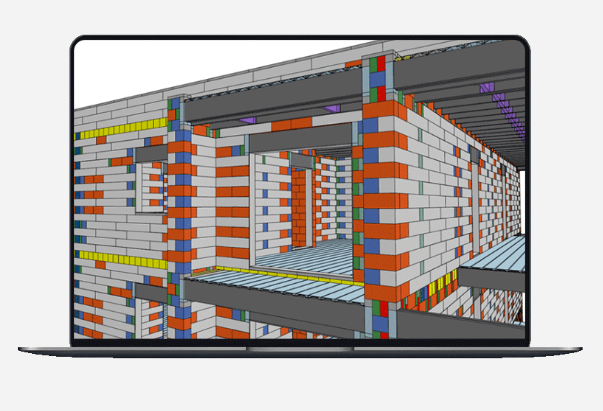

RENCO bricks are color coded and rendered in a 3-D model, enabling construction workers of varied skill sets to assemble without needing years of experience.

Why RENCO Lego Brick Building May Take Off

Industry reporters continue to share news about labor shortages in the construction industry. On top of that, the markets for traditional building materials like steel and wood have been volatile. This has prompted RENCO to ideate a new way to build — a refreshing change in an industry that hasn’t evolved much in over a century. Here are some reasons why this giant lego method may catch on:

- RENCO Lego bricks are an economical choice for both labor and materials.

- By injection molding RENCO’s proprietary material, builders can form the material into any shape necessary — from structural walls, floors, joists, roof beams, roofs, and more.

- RENCO building materials require no heavy cutting, welding or masonry work.

- RENCO products are eco-friendly.

- Made with naturally occurring raw materials and newly composed materials from recycled products.

- Manufactured in an environmentally friendly manufacturing process.

- Trade contractors that need to install mechanical, electrical and plumbing equipment can use the same methods as in traditional buildings.

- RENCO blocks are incredibly durable and comparable to the longest-lasting building materials on the market.

- This building method has been able to handle the Florida heat and humidity with no issue.

- RENCO brick buildings can withstand wind speeds of 275 mph.

- The naturally occurring resin used in the injection molding wicks moisture away instead of absorbing water.

- RENCO bricks are also insect-repellent and not susceptible to termites.

- RENCO products are mold, rust, and rot resistant.

- Workers don’t require any specialized training and can be of various skill levels. Why? Since it uses color-coded plans that are easy to follow, even for new workers.

- RENCO’s blocks, joists, decking and adhesives have passed tests in ANSI-certified laboratories for structural performance, physical characteristics and fire resistance.

- No maintenance ever: With over 8 years of testing in hundreds of individual tests RENCO products experienced no need for post construction maintenance.

Giant Lego Bricks: The Future of Construction?

With companies like RENCO finding new ways to build that are faster, cheaper, and more durable than previous methods, it’s possible that more builders will use these futuristic gadgets. The Lego house built in one’s childhood can now be amplified into a life-size version while addressing current supply chain and labor shortage issues.

While building with large Lego bricks is an amazing idea, traditional new construction homes are still wonderfully built and have plenty of charm. Our builder partners are creating beautiful dream homes for our clients every day, and we’d love to help you find your forever home too. Contact us today to talk about new construction homes!